News

What Is A Ball Valve?

A ball valve is a globe valve that controls the flow of liquid or gas through a rotating ball with a hole. By rotating the ball a quarter of a turn (90 degrees) around its axis, the medium can flow through or be blocked. They are characterized by a long service life, even if the valve is not used for a long time, it can provide a reliable seal throughout the service life.

Standard (threaded) ball valve

A standard ball valve consists of a housing, a seat, a ball and a lever for rotating the ball. They include valves with two, three, and four ports, which may be internally threaded or externally threaded or a combination thereof. Threaded valves are the most common and come in many types: with approval for a specific medium or application, mini ball valves, angular ball valves, ISO top ball valves with integrated filters or discharge points, the list goes on. They have a wide range of options and large operating pressure and temperature ranges.

For more information on threaded connections, please read our ball valve Connection Types article.

Hydraulic ball valve

Hydraulic ball valves with high operating pressure ratings and resistance to hydraulic and heating oil are designed for hydraulic and heating systems. These valves are made of steel or stainless steel. In addition to these materials, the seat also makes the hydraulic valve suitable for high working pressures. These valves have seats made of polyformaldehyde (POM) and are suitable for high pressure and low temperature applications. The maximum working pressure of the hydraulic ball valve exceeds 500 bar, while the maximum temperature is up to 80°C.

Flange ball valve

The flange ball valve is characterized by its connection type. These ports are connected to the piping system through flanges that are usually designed according to specific standards. These valves typically have a full-bore design and therefore provide high flow rates. When selecting a flanged ball valve, in addition to the pressure rating, you must also check the flange compression rating, which indicates the highest pressure that the connection type can withstand. These ball valves are designed with two, three or four ports for specific media, with ISO tops and all the other features that a standard right-angle turn valve might have. They are usually made of stainless steel, steel or cast iron.

Vent ball valve

The design of the vent ball valve is almost identical to that of the standard 2-way ball valve. The main difference is that the exit port emits to the environment in the closed position. This is done by drilling a small hole in the ball and valve body. When the valve is closed, the hole aligns with the outlet and releases pressure. This is particularly useful in compressed air systems, where decompression provides a safer working environment. Intuitively, these valves look like 2-way ball valves, but in reality, they are 3/2-way ball valves due to the smaller vent holes.

Forged ball valve

Forged ball valves are made by forming alloys and metals while they are still in a solid state. Metals and alloys are bent by heating or using industrial-sized tools that provide compression forces to bend the material. Forged ball valves are more suitable for industrial applications requiring high temperature, high pressure and other harsh conditions. Materials such as brass and stainless steel can be used to manufacture forged ball valves. During the manufacturing process, the metal (or alloy) is heated, compressed, bent and shaped according to the ball valve design using a die forging machine.

Ball valve working principle

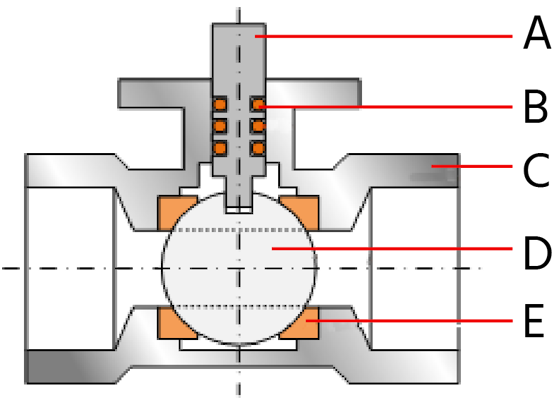

The working principle of the ball valve is generally connected to the stem to the ball (electric or pneumatic). The ball is supported and sealed by the ball valve seat and its O-ring surrounding the stem. All components are located in the valve housing. There is a hole in the sphere that, when the stem is turned a quarter of a turn, either opens to the fluid to allow the medium to flow, or closes to prevent the medium from flowing.

Besqo Marine offers a wide range of Marine Valves. For more information, leave message or send an email to sales@besqo.com.